Bulk Carriers

These vessels carry dry( grains, fertilizers, phosphates

There are also bulk carriers which can also function as tankers; such vessels are called Ore Bulk Oil ( OBO) carriers and can carry liquid cargo in wing tanks or dry bulk cargo in the centre holds.

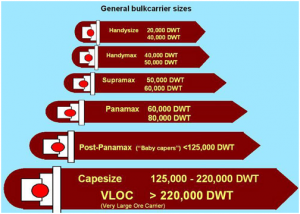

The ships that designed to carry cargo in bulk called bulk carriers. Bulkers can be segregated

- Handysize

Handy size vessels have a carrying capacity of up to 39, 999

- Handymax/ Supramax

Handymax and Supramax are bulk carriers with a capacity less than 60,000

In addition to Handysize vessels, Handymax and Supramax are counted amongst the smallest bulk carriers in operations today. A handymax vessel is typically 150- 200 m ( 490- 655ft) long with 5 cargo holds and 4 cranes of 30 metric ton lifting capacity. As they are equipped with on- deck cranes, they provide best options for carrying cargo to less sophisticated ports. These bulkers are used for transporting small volume of dry cargo, even allowing

Among handymax category, Supramax vessels are in great demand from commodity shippers due to their larger cargo carrying capacities approaching that of Panamax vessels, and

- Panamax

Panamax vessels have a carrying capacity of 60, 000- 79, 999

- Post- Panamax

Post- Panamax vessels have a carrying capacity of 80, 000– 109, 999

- Capesize

Capesize vessels have a carrying capacity of

Capesize are large- sized bulk carriers and tankers typically above 150, 000 deadweight tonnage( DWT

Capesize vessels are too large in size (especially their draught) to pass through the Panama Canal. As a result, they must transit via Cape Horn to travel between the Atlantic and Pacific oceans. Earlier, they were not fit to pass through the Suez Canal and required to take a long root via the Cape of Good Hope to travel between the Indian and Atlantic Oceans. But the deepening of the Suez Canal from 18 m ( 60 ft) to 20 m ( 66 ft) in 2009 permits most

- Very Large Ore Carriers ( VLOC)

In the subcategory of

There is a huge demand for large

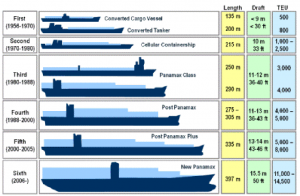

Container Vessels

In container vessels cargo is carried in containers. A container has the usual dimension of 20 or 40 feet long and 8 feet width. These vessels are

Some of the container vessels might be equipped with cranes to be able to handle the cargo operation. These are called geared container vessels. The capacity of a container vessel is defined by using the term TEU( twenty feet equivalent unit). The new generation container vessels have the capacity of 14, 000 TEU and already 18, 000 TEU- vessels have been ordered.

Multi Purpose Vessels

Main function and characteristics of a

- It transports a large variety of cargo (e. g. containers, general cargo, dry bulk cargo, wood, cars, heavy items, etc. )

- Pontoons are used to change the layout of the cargo hold, to fit the cargo. These pontoons can be used as tween decks or bulkheads.

- Vessels with cargo gear/ lifting gear: advantage they can work in ports and zones, where no cranes are available;

- Vessels without cargo gear dependent on

shore- based lifting gear; - Coastal trade liners: Have a smaller draft

- Sea- river vessels:

Have a small air draft in comparison to

other vessel of the same size, in order to be able to enter the inland waters; the masts can be lowered and also a wheelhouse which can be adjusted hydraulically in height in order to enable the vessel to pass under a bridge.

Roll-on/Roll-off Vessels

Con- Ro transports mobile cargo as well as containers. Ro- Pax is a combination of a

Refrigerated Vessels

A reefer ship is a cargo vessel

Refrigerated containers have

Also, when

- smaller hatch openings (length, width

and height); - more decks;

- lifting gear.

Cattle Carrier Vessels

Cattle ships transport livestock, such as sheep, cows, goats, camels and etc. Holds of these ships are set up stables and there should be a proper ventilation system installed. The rolling period of these vessels

Projects

Projects Bulk

Bulk Break Bulk

Break Bulk Freight

Freight Trucking

Trucking